The History of Hydraulics

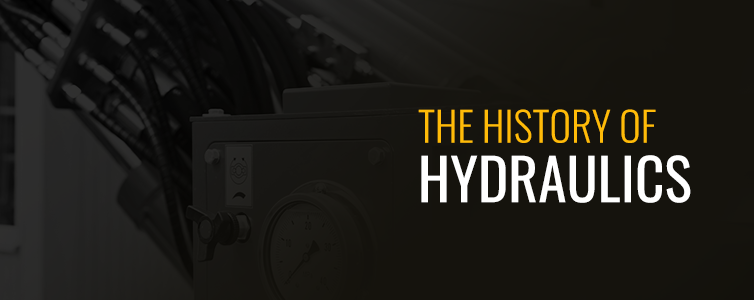

Throughout history, people have always drifted toward the water. We built cities on major waterways and used them as thoroughfares. We used running water to power wheels that helped us prepare food and fabric. Hydraulics, or the use of fluid power to run machinery, have been around for quite a while — for over 2000 years.

Explore the Rest of Our Hydraulic Systems Guide:

Who Invented Hydraulics?

Hydraulics works on the principle of fluid to generate, control and transmit power, but it is hard to pinpoint from where this principle originated. Would it be from Archimedes who thought of the Archimedes screw, which raises water? Is it further back to the Egyptians who used the principle with their canals and the shaduf, which lifts water?

Hydraulic systems have been created from the work of great minds like Joseph Bramah, Blaise Pascal, Galileo Galilei and Leonardo da Vinci. Hydraulics eventually found their place in the modern world with wide-reaching and powerful applications.

Ancient Hydraulics in Greece and Rome

Though ancient hydraulic systems have existed across cultures, our word “hydraulic” has its roots in the Greek language. The Greeks developed complex systems of water and hydraulic power, including irrigation systems, canals and aqueducts.

Aqueducts provided a way for cities to get a reliable supply of water from nearby sources and carry it to them for easy access. With the help of aqueducts, civilizations could settle in areas not immediately beside a major water source. One of these impressive aqueducts is the Tunnel of Eupalinos, an aqueduct built in Samos in the sixth century BC. It supplied water to Samos from across Mount Kastro, also known as Mount Castro.

The Greeks were no strangers to impressive feats of engineering. Though Ctesibius of Alexandria is more known for his work in pneumatics, he also dabbled in hydraulics. He developed an advanced version of a water clock that included a moving pointer and alarms. He also made a water organ that used the weight of water instead of lead to play the pipes. Following in Ctesibius’ footsteps, Hero of Alexandria developed many control systems as well, including the following:

- The setup for an automated, mechanical play

- The first known steam engineer Aeolipile

- A vending machine that dispensed holy water when someone placed a coin in it

Another major hydraulic invention attributed to a Greek is the water, or Archimedes’, screw. This screw was a major component of ancient irrigation methods. It is the oldest positive displacement pump, dating back to Ancient Egypt, where it was used on the Nile — likely before Archimedes’ time, even though he tends to get the credit. Some even believe it was used to irrigate the Hanging Gardens of Babylon, one of the Seven Wonders of the Ancient World.

Further east, the ancient Persians completed the Shushtar Historical Hydraulic System in the third century CE. This system was a colossal engineering project and served a variety of purposes, including water supply, irrigation, mills, river transportation and a defensive system. Similarly, the Sri Lankans built elaborate large-scale irrigation systems and developed the concept of a valve tower to regulate the escape of water. Their systems were developed over 2000 years ago in response to water availability that was difficult to manage.

The Romans, like the Greeks, are known for their advanced engineering skills, including roads, bridges and aqueducts, many of which are still in use today.

Aqueducts systems on their own could have inconsistent flow rates. To combat this, the Romans installed regulation devices in-stream and created reservoirs and cisterns at the ends to bring more reliable water supply to the people. A large aqueduct could store enough water for a city for 1-3 weeks, depending on the population and water restrictions.

The vast Roman aqueducts are just one example of hydraulic power. The Romans also had many water mills and developed “hushing,” an early version of hydraulic mining, for use on gold fields in the region. This method involved building up a plentiful supply of water, through dams or vessels, and releasing it into a mining area. This flood of water would wash away the lighter sediment and leave the prized gold veins accessible. Hushing later paved the way for hydraulic mining during the California Gold Rush.

How Our Understanding of Hydraulics Changed in the 17th, 18th and 19th Centuries

At the start of the 17th century, the study of hydraulics advanced with Simon Stevin’s discovery of the hydrostatic paradox and the study of non-moving water, and Galileo Galilei’s observations on gravity. Galileo studied gravitational acceleration, which played into the movement of water. His students included Evangelista Torricelli, who applied this knowledge to liquid jets and the liquid barometer, and Benedetto Castelli, who rediscovered the principle of continuity.

As a teenager, Frenchman Blaise Pascal started working on mechanical calculators and became one of the first two inventors of the device. He made contributions to mathematics — such as Pascal’s triangle — and studied hydraulic fluids. Building off the work of Torricelli and studies on vacuum space, Pascal came up with his law in 1648. Pascal’s Law says that if pressure is applied to a fluid inside of a closed system, the pressure will be equally transmitted in all directions. Essentially, the pressure within a closed system stays constant.

This principle laid the groundwork for some of the most critical hydraulic innovations in the industrial world. It defined how energy is harnessed and therefore, this principle is the basis for most modern hydraulic systems. Pascal’s work led to the invention of the hydraulic press and provided an extremely valuable principle for anything that works with fluid movement.

About a century and a half later, Joseph Bramah patented the hydraulic press in 1795. In this invention, he used Pascal’s discovery to create large amounts of power to lift heavy objects. He achieved this by multiplying a small amount of force and creating large amounts of pressure. Part of what makes the hydraulic press so useful is that a hydraulic press uses small, flexible tubing.

In 1738, Daniel Bernoulli published his book Hydrodynamica, in which he described how water behaves under certain conditions and how it reacts to equilibrium, pressure and speed. Bernoulli’s principle was based on his studies of energy conservation. Bernoulli worked closely with the mathematician Leonhard Euler, who may have derived the Bernoulli equation first. He also developed several important hydraulic equations and a hydraulic turbine.

The 19th century led to many advancements in hydraulics.

Pipe Flow and Flow Rate

Isaac Newton was studying various properties of fluids at this time. Then, Gotthilf Ludwig Hagen found the effects of temperature on pipe flow when he conducted experiments. Even though he was working off of Newton’s base of knowledge, his results were within 1% of modern measurements. His experiments involved taking fluid and injecting sawdust into it to see the motion more clearly.

Over in France, Jean Léonard Marie Poiseuille was researching flow as well, but his work was about the flow of blood through the body. His work, along with that of Hagen, was used to develop the Hagen-Poiseuille equation. This equation states that the flow rate depends on fluid viscosity, pipe length and the pressure difference between the ends. His research also led to equations on laminar flow in piping.

Hydraulic Accumulator and the Rotary Engine

In 1838, there was a man who today we call the grandfather of modern hydraulic power. William George Armstrong was one of the first to experiment with hydraulics and developed a rotary engine. Unfortunately, no one cared for it at the time. He then discovered and created electric charge from the escaped high-pressure steam of a boiler, which came to be known as the Armstrong effector. He later designed a crane with a reciprocating ram that was powered by hydraulics.

Armstrong modified an existing crane to use a town’s water supply as a power source. He started a business using this arrangement and began manufacturing cranes with this method. Later, Armstrong also developed the hydraulic accumulator, which accomplished several goals. It bypassed the need for reservoirs. By doing this, it creates a system for the hydraulic power to move between the wide-spaced hydraulic devices and allows for much higher pressures.

Introduction to Hydraulic Mining Regulations

When the California Gold Rush arrived in the United States in the 1840s, hydraulic mining developed out of the Roman “hushing” methods. This type of mining used high-pressure water jets that look like cannons to excavate rock. The machines could be 16 to 18 feet long. Workers could access much more gold by removing rock and sediment. Quickly, farmers and settlers felt the damage this method had on the environment, as miners placed the excavated soil into nearby creeks or canyons — which filled up and blocked waterways and downstream farms that relied on the water. The farmers called it “slickens,” and it led to a huge economic loss for farmers.

In 1884, the conflict between the farmers and miners escalated to a court case and led to the lawsuit of Woodruff v. North Bloomfield Gravel Mining Company. The complainants showed the damage down to the agriculture sector. They sought an injection to stop the discharging of debris into rivers. Judge Sawyer’s decision was groundbreaking for environmentalists, as he recognized the severe environmental and social impacts. He halted the practice of hydraulic mining discharging into rivers. Soon, the practice stopped as disposing of the debris in other ways became too costly.

Modern-Day Applications of Hydraulics

As the 20th century washed in, so did new, varied uses for hydraulics. Hydraulics are popular systems because they are adaptable, offering flexible hoses and small tubing, along with many different actuator types. The high-power density doesn’t hurt either.

Aside from vehicle and industrial usage, you can find hydraulic devices everywhere. You might even be sitting on one. Office chairs and dishwashers are two household objects that often use hydraulics. Other, more sophisticated machinery includes airplanes, construction equipment and elevators.

While water wheels date back to ancient times, direct currents (DC) weren’t discovered until the 19th century. But what do these have to do with each other? In both instances, you are harnessing rotational motion. The old water wheels are just a different power source of rotational energy. DC motors use an electrical current flow to turn the motor and shaft, and water wheels used the water current. DC motors are a substantial aspect of our electronic usage today.

The power of water can also be used to create electricity. Appleton, Wisconsin, was the home of the first hydroelectric power plant. Now there are more than 57,000 worldwide. Hydroelectricity is a major source of renewable energy that uses the movement of water from a dam to generate power. Hydroelectric power generation is expected to grow more than 20% in the next 25 years.

Meanwhile, in the UK

In the UK, the London Hydraulic Power Company regularly supplied water at 700 lbs. per square inch through 150 miles of piping underneath the London streets. This system, which lasted until 1977, operated curtains at the Royal Opera House, opened gates at the Thames and lifted elevators across the city.

While history would have us use water as the primary hydraulic fluid, advances in engineering have shown that water is often not the best option. Some common options for hydraulic fluid are:

- Mineral oil

- Natural oils, like canola

- Synthetic compounds

People choose their hydraulic fluids with various purposes and characteristics in mind, like viscosity, density, environmental impact, weight and cost. A fluid’s responses to heat, evaporation and other materials are also factors. Some fluids are designed to keep low contamination levels while others may be designed to stand up to extremely high heat or radiation. These fluids can be used in anything from military applications to industrial machinery to the brake fluid in your car.

Technology Advances

Now, with the advent of computer technologies and advanced data gathering methods, researchers can study fluid movements with more precision and more depth. The blending of hydraulics and electronics is also booming. They allow for more advanced machine operations, so an operator can take much more accurate and detailed action. Electronic controls for a hydraulic system are not uncommon.

One place you’ll find plenty of hydraulic machinery is on a construction site. Cranes, bulldozers and all sorts of heavy equipment are run using hydraulic drives. The pressurized fluid systems are incredibly common in a variety of vehicle types. A hydraulic pump and motor have a higher power density than an electric motor and generator — 16:1 by weight, and 8:1 by volume, to be specific. They also offer precise controls that are often electrically operated.

Another area that has seen significant advantages from hydraulic systems is agriculture. Farming equipment was now capable of more robust applications. Many pieces of farming equipment use hydraulics to drive and move components, such as the Ford-Ferguson tractor.

Aerospace applications are also heavily invested in the use of hydraulics. Hydraulic systems power many parts of a plane, including things like brakes, cargo doors, steering, propeller control and wing flaps.

Hydraulic Repair and Information

Hydropower is one of the most widely used and oldest forms of energy. Its applications range from irrigation to construction equipment and heavy machinery. It is so widespread that you probably have some type of hydraulic equipment in your home or office building.

The remarkable engineers of the past paved the way for contemporary systems that adapted and grew to meet the needs of the modern world.

Engineers at Hard Chrome Specialists have more than 75 combined years of experience working with hydraulic pumps, valves and motor repair. If you find that you have a broken hydraulics system and need repair, or want to learn more about hydraulics, Hard Chrome Specialists can help. We are family-owned and operated and strive to meet all your hydraulic repair needs. Contact us today!